POWER INDUSTRY

KLES's technologic competencies contribute to stabilizing the operation of power generation facilities, including but not limited to ‘SKYFFOLDING™ Systems’ scaling up work efficiency with safety for boiler maintenances, ‘Safety Plus System’ augmented with ICT, ‘Snubber _Hydraulic pipe shock absorber’ fabricated with glocalized technology, as well as ‘MRO services’ carried through by the expert technicians.

SKYFFOLDING™

SKYFFOLDING™ Systems, A flagship brand of KLES, first off build up 'Hydraulic lifting system' on the topmost of the boiler (Heavy girder), and then platform-supported pendant scaffolds assembled at ground/Zero level are lashed down with wire ropes and lifted up at intervals to systematize the upper & the lower scaffold lifting system each, whereupon stepping up work efficiencies by way of stabilization of the system with minimized swaying, while proactively warding off workplace disaster arising from the chain reaction triggered by a failure of a member component in the case of the conventional upright scaffold. Currently, the system has been adopted and operated in most domestic thermal power plants in Korea, over 98%.

Safety Plus

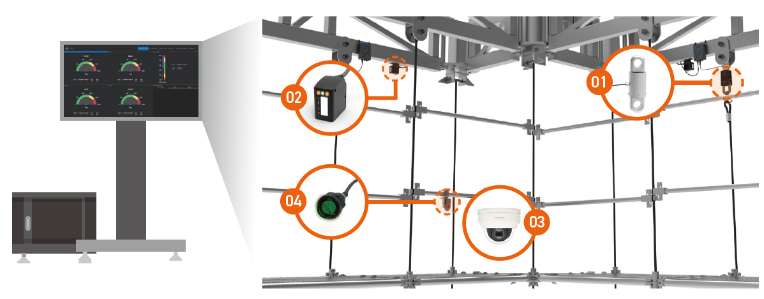

This Smart in-furnace scaffolding safety-management system has been designed and developed for the safety and security of the workmen who are working inside the dark and noisy furnace. Organizing the system coupled with SKYFFOLDING™ Systems, you can efficiently manage the safety of the scaffolding along with the wellness of workers in the furnace exposed to many kinds of dangers, by means of installing ‘the load measurement’, ‘the displacement measurement’, ‘the workman monitoring [IR/IP camera]’, and ‘the alarm modules’. In addition, it can be extensively applied to various construction and maintenance environments such as system scaffolding.

SPPMS

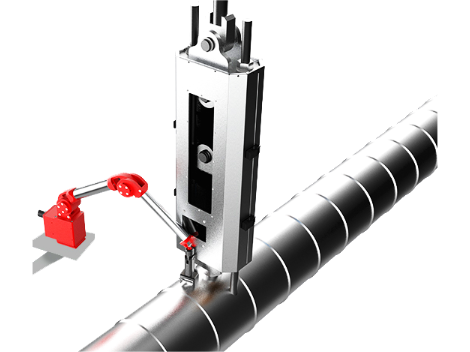

SPPMS (Smart Power Piping Management System) is a pipe management system geared to thermal power plants, beefed up with realtime pipe status monitoring and life assessment technology. Power piping bridging boiler header to turbine inlet, carrying hot and high-pressure steam way long, is subjected to the degradation and deformation at ease, which would cause fatal damage to the piping eventually. Damage to the piping can trigger the failure of the main unit or peripherals, even worse, likely leading to the shutdown of the power plant to incur huge socio-economic losses. SPPMS monitors the condition of pipes in realtime to prevent such pipe accidents predictably, which comprise a '3D pipe displacement measuring device' managing realtime 3D movements of power piping, a 'temperature monitoring sensor' sensing the temperature, and an 'applied load measuring device' monitoring the self-weight and load. Each measuring device puts forth basic data through which enabling comprehensive assessment and interpretation of the pipe conditions.

Hydraulic Snubber

The need arose to design and engineer a compatible device that not only never restrains the movement of the piping even when 3D displacement different from the design breaks out, but also protects the piping and the main equipment from the strikes of dynamic loads of random directions. It is a supporting device that curbs various types of troubles arising from dynamic loads generated in & outside of the power generation facility including main equipment and pipelines, while avoiding the creation of additional thermal stresses by absorbing the designed thermal displacement. This Multiaxial hydraulic pipe shock absorber is so sophisticatedly designed and fabricated to respond to and absorb the shocks in random directions, breaking through the unilateral performance of the conventional shock absorber limited to responding to only one direction.