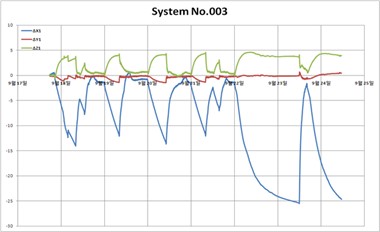

3D Pipe Displacement Measuring

Utilized as vital data for evaluating equipment integrity and life assessment, through comparative analysis with the designed of 3D pipe displacement.

Measurement method

Measuring tri-axial displacement during operation

- Measurement range: ±200mm per axis

- Accuracy: ±0.5mm per axis

- Measurement interval: Once in a min.

Reference standard

Specifications

Track records

- KHNP - Hanul pp. #3,4,6

- KHNP - Hanbit#5

- KHNP - Shingori pp. #1,2

- KHNP - Hanul pp. #5

- KHNP - Hanbit pp. #6

- KHNP - Shinwolsong pp. #1

- United Arab Emirates | BNPP #3,4

- United Arab Emirates | BNPP #3

- KHNP - Shinhanul pp. #1

- KHNP - Shingori pp. #4

- KHNP - Hanul pp. #1,2

- KHNP - Samcheok Bitdream pp. #1, 2

- United Arab Emirates | BNPP #1, 2

- United Arab Emirates | KHNP - Hanul pp. #1

- KHNP - Shingori pp. #3

- KHNP - Shinwolsong pp. #2

- KHNP - Shinwolsong pp. #1

- KHNP - Shingori pp. #2

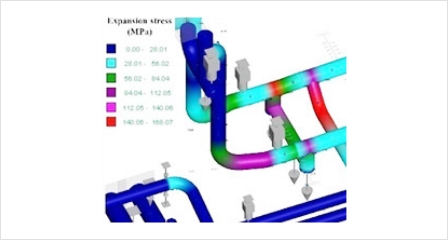

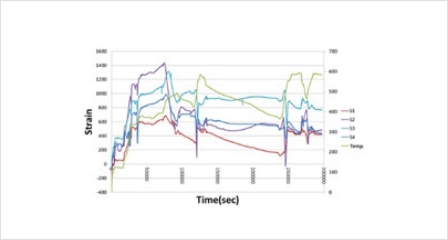

Stress & Strain Measuring

Identifying the root cause of equipment failure and assessing its integrity, in case of breaking out before the end of its design life.

Measurement method

Stress analysis (Point selection)

- AutoPipe(Version V8i)

- Ansys Mechanical (V 16.0)

SG installation and data analysis

- Measurement range: Max. 650℃

- Storage Interval: Once in a min.

Reference standards

ASTM E251

Strain Gauge User’s guide TML