Safety Plus System Smart Scaffolding Safety-management System _SSSS

This Smart in-furnace

scaffolding safety-management system has been meticulously designed and developed to ensure the

safety and security of the workmen who are working inside the dark and noisy furnace.

Organizing the system coupled with SKYFFOLDING™ Systems, you can efficiently manage the

safety of the scaffolding along with the wellness of workers in the furnace overly exposed to

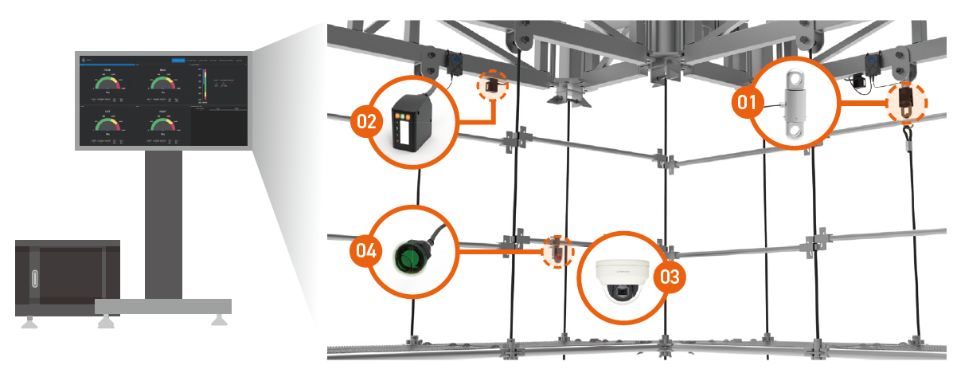

many kinds of potential hazards, by means of installing ‘the load measurement’,

‘the deformation measurement’, ‘the workman monitoring’, and ‘the

alarm’ modules.

In addition, it can be

extensively applied to a range of construction and maintenance environments such as system

scaffolding.

Failsafe configurations

Realtime monitoring of load distribution onto in-furnace scaffolds, wherewith preventing any accidents on account of the unbalanced load across the system.

Measuring the deformation of the support structure (Platform), in order to monitor any outbreak of deformation or displacement anomaly.

Network screening all four sides and corners throughout the boiler so that you can track the location and status of the workmen in real time in case he or they are left in the furnace, by putting into use IP cameras featuring pan & tilt - zoom in/out - motion detection functions all together.

Alarming potential dangers to workers staying in the furnace in the event any contingency signal(s) is detected, including overloads exceeding the rated or working load onto in-furnace scaffolds.

Compiling and storing measured load and deformation data, with the server and client software configured. Activating the alarm system when abnormal load or deformation / displacement is detected, so as to warn the workers of such danger. Managing load and deformation trends and system errors, by referring to the history inquiry function.

Outsmarting Security Features

Detecting in real time if any sudden outbreak of eccentric load or abnormal deformation of the scaffold support structure, so as to immediately trigger an alarm against the danger to in-furnace workers when such an abnormal signal(s) takes place; which shall relieve the workers from worksite anxiety as well as ramp up supervisory capabilities. Besides, the system can check out if any presence of residual workers inside the furnace workplace, after installing/disassembling the scaffolding or repairing the boiler putting the scaffold to use.

Utilization of the 'Safety Plus' management program, mounting user-friendlier interface enabling data visualizationSafety Plus is configured with the Server system and the Client system. The Server collects, stores, and manages the load and deformation data in real time. Particularly, on the Safety Plus Viewer program installed in the Client system, the user can monitor in 3D the scaffold state and the whereabouts of the checked-in workers in real time, alongside the functions of real-time thermal image verification, data history trend analysis, alarm history trace management, etc.

Safeguarding against the scaffold system deformation or collapseRealtime monitoring of the loads acting on the scaffolds and the displacements of the boiler tube makes it feasible to take immediate action in response to the outbreak of abnormalities across the system

Building up a worksite of security and wellness (Option)The workman monitoring module is designed to check in on any workman if left behind, taking advantage of temperature information acquired from the IR camera; simultaneously to check in & out workmen by tracking their whereabouts through wearable gear; additionally to check up on the wholesomeness at the worksite using wireless sensors, such as temperature, humidity, oxygen & carbon dioxide, and dust concentration.

Safety Plus Viewer

Certificate & Patent

Boiler in-furnace scaffold Smart safety management system

in-Furnace scaffold Safety monitoring program

Smart management system for superheated steam piping for thermal power plants

in-Furnace scaffold Smart

Track Records

- KOMIPO - Shin-Seocheon pp. #1

- KOSPO - Samcheok pp. #1,2

- KOEN - Yeongheung pp. #5,6

- KOMIPO - Shin-Boryeong pp. #1,2

- KOSPO - Hadong pp. #1~8

- EWP - Dangjin pp. #9,10

- GS DEP - Bukpyeong pp. #1,2

- KOSPO - Hadong pp. #6,7

- KOSPO - Hadong pp. #3