Provision of Reliable Maintenance for Power Plant Pipes and Boilers

KLES have been rendering the Big-five domestic power companies and Korea Hydro & Nuclear Power Co., Ltd. with maintenance services related to pipes and boilers, and are actively working toward winning export projects. The safer and smoother maintenance services for pipe and boiler support devices are delivered taking advantage of brand-new technology-fueled products, technical competencies, and veteran engineers.

Hanger Maintenance & Reinstallation

KLES are carrying out overhauls, and inspections & evaluations with respect to various types of plant equipment and facilities, in the cold state being shut down of plant operation in accordance with mid-to long-term planned maintenance plans, related laws, and technical compliance standards, where the top-notch service is furnished under systematic and scrupulous schemes mapped out in readiness, taking full advantages of cumulative maintenance technology of the company, expertise workforces in each field, and exquisite tools and equipment.

KLES are not only helping out bring equipment usage up by reducing the equipment failure rate while in operation through planned preventive maintenance, but also substantially contributing to the saving of plant operating expenses by making it happen to optimize the overhaul period downwards to the satisfaction for customer requirements.

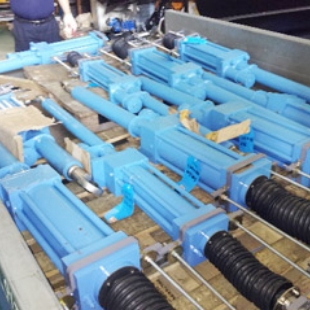

Snubber Maintenance

Periodic inspection and maintenance procedures are very essential to maintain the performance of the snubber installed on the power plant. KLES operates maintenance of the snubber with the following processes:

- Check the snubber status

- Surface cleaning

- Disassembly and inspection of the internal condition

- Internal cleansing

- Maintenance (old consumables and aged parts to be replaced, oil replacement, etc.)

- Painting

- Performance evaluation

Inspection & Emergency Maintenance

KLES play a contributive role in securing the integrity of facilities following commercial operation through participation in maintenance work during commissioning periods in the final stage of power plant construction, while exercising preventive inspections for efficient maintenance and management of the equipment already installed, until its commercial operation, and also carry out emergency restoration work for machines and high-temperature equipment that fail or malfunction during operation.

Boiler Sling Rod load control

The tube bank, header, and the like, which are the main equipment composing the boiler body, get supported by the main body suspension structure, commonly called Sling rod, which is installed onto the topmost place of the boiler section, named Penthouse. It is designed to maintain the balance in the way to support the entire loads of the boiler, in junction with the boiler internal structure as a supporting point. However, influenced by the traveling of the loads in the course of operation of the plant, the support load exceeding the design load arises, resulting in uneven load distributions. Whereupon, the comparative analysis between the design load and the measured by each row of the Sling rod is to be conducted so that such biased loads could be reallocated evenly, thereby ensuring overall stability and safety of the boiler equipment.

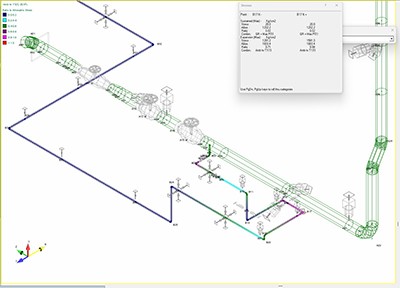

Pipe Stress Analysis at high temperature and high pressure

High temperature & pressure pipes and LNG pipes (LNG of -162°C in the liquid state passes through the pipe) for power generation will be subjected to fatigue loads repetitively in the wake of thermal contractions and expansions. By means of stress interpretation of the pipe system based on data of the actual operation history and the current state of pipes, the high-stress section can be identified, and thereby the integrity of the pipes gets to be assessed.

Total Solutions for Pipe Vibration Reduction

When abnormal vibrations arise out of high temperature/pressure pipes and rotating machines, a vibration reduction solution is served through analysis and interpretation of the measured results.